MT-BSL-H75K hpfr The voltage and current of the motor can be adjusted to a sine wave MITSUBISHI MT-BSL-H75K

Brand:

MITSUBISHI

Name: Sine wave filter

Model: MT-BSL-H75K

Power: 75kw.

Voltage: 200V.

Sine wave filter.

The voltage and current of the motor can be adjusted to a sine wave.

The sine wave filter is installed to the output terminal of the inverter.

Applicable to FR-A820-03800 (75K) above and FR-A840-02160 (75K) and above frequency converter.

Sine wave filter is equivalent to the operational characteristics of the sine wave power driver, can provide the following benefits.

Low noise.

No surge current.

Reduce motor loss (standard motor).

...More relevant models >>>>

Name: Sine wave filter

Model: MT-BSL-H75K

Power: 75kw.

Voltage: 200V.

Sine wave filter.

The voltage and current of the motor can be adjusted to a sine wave.

The sine wave filter is installed to the output terminal of the inverter.

Applicable to FR-A820-03800 (75K) above and FR-A840-02160 (75K) and above frequency converter.

Sine wave filter is equivalent to the operational characteristics of the sine wave power driver, can provide the following benefits.

Low noise.

No surge current.

Reduce motor loss (standard motor).

Parameter setting can be carried out without the power supply of the inverter.Power: 15kw.

Voltage: 200V.

The power factor of the input power factor is up to 0.99 and above (100% load).

Can be connected to multiple inverters, to achieve a common DC bus mode.

Equipped with standard power retrogradation function MITSUBISHI MT-BSL-H75K. Length: 30 meters.

Cable manufacturing specifications.

When there is no connection options, according to the table under the cable MT-BSL-H75K

Using a parallel connection or a large size cable for connection between the terminal PG" and "SD" and the motor end encoder. "Power: 7.5kw.

Purpose: to suppress the power harmonics.

Improve the power factor, reduce the input side of the high harmonic current MITSUBISHI MT-BSL-H75K.

Make sure that this option is installed in the FR-A820-03800 (75K) and FR-A840-02160 (75K) and above capacity and above capacity.

At the same time the installation options in the use of 75kW and above motor. (the IP55 series has a built-in DC reactor.)

According to the motor power used to select the DC reactor.

(when the inverter capacity is greater than the motor capacity, is still based on the motor capacity to choose MITSUBISHI MT-BSL-H75K. ) MITSUBISHI inverter series: FR-F820.

Voltage level: three phase 200V.

Power: 5.5kw.

SLD converter rated current: 34A.

Structure and function: Standard model.

Type: CA MITSUBISHI hpfr.

Substrate coating: have.

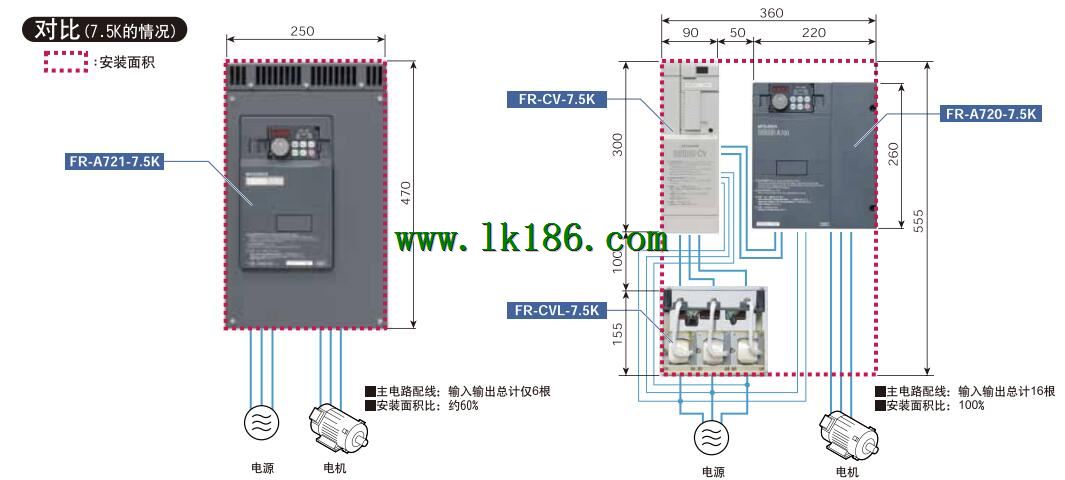

Compatibility with existing models.

Transducer installation size and FR-F700 (P) series of the same, so you do not need to worry about the replacement operation MITSUBISHI hpfr.

(rectifier separation type will vary)

Also, but also through the use of options (FR-A8TAT), FR-F700 (P) series installed control loop terminal station.

Built in 2 PID arithmetic. In the inverter can be PID control of the motor state at the same time, used in the control of the external machine MITSUBISHI hpfr.

No external PID controller is used to control the external machine, so the system cost can be reduced. MITSUBISHI inverter FR-F720 series.

Voltage level: three phase 200V.

Frequency converter capacity: 7.5KW.

When the inverter is running, the starting current and starting torque of the motor are how?

With the operation of the inverter, with the acceleration of the motor to improve the frequency and voltage,

The starting current is limited to 150% below the rated current (according to the different types of aircraft, 125%~200%).

Starting with power frequency power supply, the starting current is 6~7 times of the ratted current, therefore, the impact on the mechanical and electrical MT-BSL-H75K.

The inverter drive can be smoothly start (start time longer).

The starting current is 1.2~1.5 times of the rated current, and the starting torque is 70%~120%% rated torque;

For the inverter with the torque automatic enhancement function, the starting torque is more than 100%, which can start with full load MITSUBISHI MT-BSL-H75K.

Voltage: 200V.

The power factor of the input power factor is up to 0.99 and above (100% load).

Can be connected to multiple inverters, to achieve a common DC bus mode.

Equipped with standard power retrogradation function MITSUBISHI MT-BSL-H75K. Length: 30 meters.

Cable manufacturing specifications.

When there is no connection options, according to the table under the cable MT-BSL-H75K

Using a parallel connection or a large size cable for connection between the terminal PG" and "SD" and the motor end encoder. "Power: 7.5kw.

Purpose: to suppress the power harmonics.

Improve the power factor, reduce the input side of the high harmonic current MITSUBISHI MT-BSL-H75K.

Make sure that this option is installed in the FR-A820-03800 (75K) and FR-A840-02160 (75K) and above capacity and above capacity.

At the same time the installation options in the use of 75kW and above motor. (the IP55 series has a built-in DC reactor.)

According to the motor power used to select the DC reactor.

(when the inverter capacity is greater than the motor capacity, is still based on the motor capacity to choose MITSUBISHI MT-BSL-H75K. ) MITSUBISHI inverter series: FR-F820.

Voltage level: three phase 200V.

Power: 5.5kw.

SLD converter rated current: 34A.

Structure and function: Standard model.

Type: CA MITSUBISHI hpfr.

Substrate coating: have.

Compatibility with existing models.

Transducer installation size and FR-F700 (P) series of the same, so you do not need to worry about the replacement operation MITSUBISHI hpfr.

(rectifier separation type will vary)

Also, but also through the use of options (FR-A8TAT), FR-F700 (P) series installed control loop terminal station.

Built in 2 PID arithmetic. In the inverter can be PID control of the motor state at the same time, used in the control of the external machine MITSUBISHI hpfr.

No external PID controller is used to control the external machine, so the system cost can be reduced. MITSUBISHI inverter FR-F720 series.

Voltage level: three phase 200V.

Frequency converter capacity: 7.5KW.

When the inverter is running, the starting current and starting torque of the motor are how?

With the operation of the inverter, with the acceleration of the motor to improve the frequency and voltage,

The starting current is limited to 150% below the rated current (according to the different types of aircraft, 125%~200%).

Starting with power frequency power supply, the starting current is 6~7 times of the ratted current, therefore, the impact on the mechanical and electrical MT-BSL-H75K.

The inverter drive can be smoothly start (start time longer).

The starting current is 1.2~1.5 times of the rated current, and the starting torque is 70%~120%% rated torque;

For the inverter with the torque automatic enhancement function, the starting torque is more than 100%, which can start with full load MITSUBISHI MT-BSL-H75K.

...More relevant models >>>>

Related download