A1S55B PLC programming language through the preparation of specifications, in accordance with the actual needs of the use of the function to design MITSUBISHI A1S55B

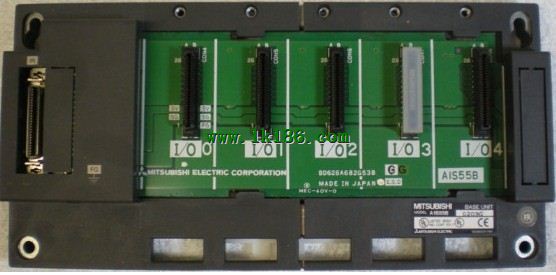

Brand:

MITSUBISHI

Name: Extended bottom plate

Model: A1S55B

5 slots.

Installation of the power unit can not be used for AnS QnAS/ series units installed.

The popularization and application of PLC programming has been developed rapidly in our country,

It has been widely used in all kinds of mechanical equipment and production process of electrical control devices,

All walks of life have emerged a large number of application of PLC transformation of the results of the equipment.

Understand the working principle of PLC, have the ability to design, debug and maintain the PLC control system,

Has become the basic requirements of modern industry for electrical technicians and engineering students.

PLC user program is designed according to the control system of the process control requirements,

PLC programming language through the preparation of specifications, in accordance with the actual needs of the use of the function to design.

As long as the user can master some kind of standard programming language,

To be able to use PLC in the control system,

To achieve a variety of automatic control functions.

...More relevant models >>>>

Name: Extended bottom plate

Model: A1S55B

5 slots.

Installation of the power unit can not be used for AnS QnAS/ series units installed.

The popularization and application of PLC programming has been developed rapidly in our country,

It has been widely used in all kinds of mechanical equipment and production process of electrical control devices,

All walks of life have emerged a large number of application of PLC transformation of the results of the equipment.

Understand the working principle of PLC, have the ability to design, debug and maintain the PLC control system,

Has become the basic requirements of modern industry for electrical technicians and engineering students.

PLC user program is designed according to the control system of the process control requirements,

PLC programming language through the preparation of specifications, in accordance with the actual needs of the use of the function to design.

As long as the user can master some kind of standard programming language,

To be able to use PLC in the control system,

To achieve a variety of automatic control functions.

Available network: 10BASE2.

Max / total distance: 185/925m.

A1SJ71E71 is a compact Ethernet interface module,

Used to hang PLC series ANS to ethernet.

There are two kinds of hanging network modules: A1SJ71E71-B2-S3 and A1SJ71E71-B5-S3 respectively corresponding to 10BASE2 and 10BASE5,

So that the vast majority of installed cable can continue to use MITSUBISHI A1S55B. Position detection axis number: 1 axis A1S55B

Resolution: 4096 * 32 * 409.6 * 320.

Number of output channels: 16 channels.

When communicating in the PLC network of MITSUBISHI,

There is no sense of difference and discontinuity in the network,

Can carry on the remote monitoring, modification, debugging and other work of data communication and program,

Without taking into account the level and type of network MITSUBISHI A1S55B.

MELSECNET/H and CC-Link use the way of loop communication,

Periodically automatically send and receive messages,

Does not require specialized data communication procedures,

Simple parameters can be set.

MELSECNET/H and CC-Link are used to transmit and receive the broadcast mode,

This can be done on the network data sharing.

For the use of Ethernet, MELSECNET/H, CC-Link network,

Can set the network parameters and various functions, simple and convenient in the Developer GX software screen MITSUBISHI A1S55B. Program memory capacity: 8k.

Input / output points: maximum 256 points.

With base plate and power supply.

PLC is the use of " sequential scanning, and constantly circulating " way to work MITSUBISHI Extended bottom plate.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence number (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next round of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work MITSUBISHI Extended bottom plate MITSUBISHI Extended bottom plate.

With the rapid development of microprocessor, computer and digital communication technology,

Computer control has been extended to almost all industrial fields.

Modern society requires manufacturing to respond quickly to market demand,

Production of small quantities, multi varieties, multi specifications, low cost and high quality products,

In order to meet this requirement,

Production equipment and automatic production line control system must have high reliability and flexibility,

PLC programming is to comply with the requirements of the emergence of it is based on a microprocessor based general industrial control device.

PLC programming is a digital computing operation of the electronic system,

Designed for applications in industrial environments.

It uses programmable memory,

An instruction used to perform logicall operations, sequence control, timing, counting and arithmetic operations in its internal storage,

And through the digital, analog input and output, control of various types of machinery or production process A1S55B.

Programmable controlller and related equipment,

Should be easy to make the industrial control system to form a whole, easy to expand the principle design of its functions MITSUBISHI A1S55B.

Max / total distance: 185/925m.

A1SJ71E71 is a compact Ethernet interface module,

Used to hang PLC series ANS to ethernet.

There are two kinds of hanging network modules: A1SJ71E71-B2-S3 and A1SJ71E71-B5-S3 respectively corresponding to 10BASE2 and 10BASE5,

So that the vast majority of installed cable can continue to use MITSUBISHI A1S55B. Position detection axis number: 1 axis A1S55B

Resolution: 4096 * 32 * 409.6 * 320.

Number of output channels: 16 channels.

When communicating in the PLC network of MITSUBISHI,

There is no sense of difference and discontinuity in the network,

Can carry on the remote monitoring, modification, debugging and other work of data communication and program,

Without taking into account the level and type of network MITSUBISHI A1S55B.

MELSECNET/H and CC-Link use the way of loop communication,

Periodically automatically send and receive messages,

Does not require specialized data communication procedures,

Simple parameters can be set.

MELSECNET/H and CC-Link are used to transmit and receive the broadcast mode,

This can be done on the network data sharing.

For the use of Ethernet, MELSECNET/H, CC-Link network,

Can set the network parameters and various functions, simple and convenient in the Developer GX software screen MITSUBISHI A1S55B. Program memory capacity: 8k.

Input / output points: maximum 256 points.

With base plate and power supply.

PLC is the use of " sequential scanning, and constantly circulating " way to work MITSUBISHI Extended bottom plate.

That is, in the operation of CPU, PLC according to the user according to the control requirements of the coexistence of the user in the memory of the program,

According to the instruction sequence number (or address number) for periodic cyclic scan, such as no jump instruction,

From the first instruction to the user program execution sequence one by one, until the end of the program,

And then return to the first command, start the next round of the new scan, in the process of each scan,

Also complete the sampling of the input signal and the output status of the refresh and other work MITSUBISHI Extended bottom plate MITSUBISHI Extended bottom plate.

With the rapid development of microprocessor, computer and digital communication technology,

Computer control has been extended to almost all industrial fields.

Modern society requires manufacturing to respond quickly to market demand,

Production of small quantities, multi varieties, multi specifications, low cost and high quality products,

In order to meet this requirement,

Production equipment and automatic production line control system must have high reliability and flexibility,

PLC programming is to comply with the requirements of the emergence of it is based on a microprocessor based general industrial control device.

PLC programming is a digital computing operation of the electronic system,

Designed for applications in industrial environments.

It uses programmable memory,

An instruction used to perform logicall operations, sequence control, timing, counting and arithmetic operations in its internal storage,

And through the digital, analog input and output, control of various types of machinery or production process A1S55B.

Programmable controlller and related equipment,

Should be easy to make the industrial control system to form a whole, easy to expand the principle design of its functions MITSUBISHI A1S55B.

...More relevant models >>>>

Related download