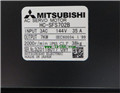

MITSUBISHI HC-SFS702BG1 1/17 HC-SFS702BG1 1/17

- Brand: MITSUBISHI(Mitsubishi)

- Country: JAPAN

- Name:

- Model: HC-SFS702BG1 1/17

- Price: U.S.$ 9837.29

MITSUBISHI HC-SFS702BG1 1/17

Servo motor series: low inertia, small capacity.

Rated output: 3.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: there.

Oil seal: have.

Corresponding servo amplifier: MR-JE-10B/MR-JE-10A.

Support position control, speed control, torque control, push and press control.

Position control can use linear, arc interpolation controller, fixed size feed control, target position change and other rich functions HC-SFS702BG1 1/17

The position control and torque control are realized by switching control mode.

The gain adjustment of servo can be simply performed by the advanced one key tuning function.

At the same time, it is also able to suppress the low frequency vibration of the manipulator by the advanced vibration suppression control II,

Shorten the time to complete the positioning, so as to achieve the production of the rhythm of the shortening MITSUBISHI HC-SFS702BG1 1/17. Program capacity: 252 K step.

Input / output points: 4096 points.

Number of input and output elements: 8192.

Processing speed: 0.034 s.

Program memory capacity: 1008 KB MITSUBISHI HC-SFS702BG1 1/17.

Support USB and RS232.

CPU module expansion standard RAM (max 8MB).

Can be used with the SD memory card at the same time .

Continuous access file register.

Ultra high speed processing, production time is shortened, better performance.

As applications become larger and more complex, it is necessary to shorten the system operation cycle time.

The operation period can be shortened by the super high basic operation speed 1.9ns.

In addition to achieve in the past with the control of single-chip high-speed control,

The system performance can be improved by reducing the total scan time,

To prevent any possible performance bias.Cable length: 1.5 meters.

For FXCPU (FX0, FX0S, FX0N, FX1S, FX1N, FX2N, FX2NC,) and GOT connection.

For FXCPU expansion board FX2N-422-B, FX1N-422-BD and GOT connection. Motor series: low inertia, small capacity.

Using a serial absolute / incremental encoder.

Rated output power: 0.1kw.

Rated speed: 3000rpm.

With the brake with brake.

Without GB.

Shaft end: straight shaft.

A servo motor is an engine that controls the operation of the mechanical components in the servo system.

Servo motor can make the control speed, position accuracy is very accurate, can be converted to torque and speed voltage signals to drive the control object.

Servo motor rotor speed is controlled by the input signal, and can quickly response,

In the automatic control system, used as actuators, and ellectromechanical time constant, high linearity, initiating voltage characteristics,

The signal can be converted into a motor shaft on the angular displacement or angular velocity output HC-SFS702BG1 1/17.

Divided into DC and AC servo motor two major categories, the maain features are,

When the signal voltage is zero, there is no rotation,

The speed increases with the increase of the torque and the speed decreases HC-SFS702BG1 1/17.

HC-SFS702BG1 1/17 Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HC-SFS702BG1 1/17&select=5

Rated output: 3.0kw.

Rated speed: 2000r/min.

Electromagnetic brake: there.

Oil seal: have.

Corresponding servo amplifier: MR-JE-10B/MR-JE-10A.

Support position control, speed control, torque control, push and press control.

Position control can use linear, arc interpolation controller, fixed size feed control, target position change and other rich functions HC-SFS702BG1 1/17

The position control and torque control are realized by switching control mode.

The gain adjustment of servo can be simply performed by the advanced one key tuning function.

At the same time, it is also able to suppress the low frequency vibration of the manipulator by the advanced vibration suppression control II,

Shorten the time to complete the positioning, so as to achieve the production of the rhythm of the shortening MITSUBISHI HC-SFS702BG1 1/17. Program capacity: 252 K step.

Input / output points: 4096 points.

Number of input and output elements: 8192.

Processing speed: 0.034 s.

Program memory capacity: 1008 KB MITSUBISHI HC-SFS702BG1 1/17.

Support USB and RS232.

CPU module expansion standard RAM (max 8MB).

Can be used with the SD memory card at the same time .

Continuous access file register.

Ultra high speed processing, production time is shortened, better performance.

As applications become larger and more complex, it is necessary to shorten the system operation cycle time.

The operation period can be shortened by the super high basic operation speed 1.9ns.

In addition to achieve in the past with the control of single-chip high-speed control,

The system performance can be improved by reducing the total scan time,

To prevent any possible performance bias.Cable length: 1.5 meters.

For FXCPU (FX0, FX0S, FX0N, FX1S, FX1N, FX2N, FX2NC,) and GOT connection.

For FXCPU expansion board FX2N-422-B, FX1N-422-BD and GOT connection. Motor series: low inertia, small capacity.

Using a serial absolute / incremental encoder.

Rated output power: 0.1kw.

Rated speed: 3000rpm.

With the brake with brake.

Without GB.

Shaft end: straight shaft.

A servo motor is an engine that controls the operation of the mechanical components in the servo system.

Servo motor can make the control speed, position accuracy is very accurate, can be converted to torque and speed voltage signals to drive the control object.

Servo motor rotor speed is controlled by the input signal, and can quickly response,

In the automatic control system, used as actuators, and ellectromechanical time constant, high linearity, initiating voltage characteristics,

The signal can be converted into a motor shaft on the angular displacement or angular velocity output HC-SFS702BG1 1/17.

Divided into DC and AC servo motor two major categories, the maain features are,

When the signal voltage is zero, there is no rotation,

The speed increases with the increase of the torque and the speed decreases HC-SFS702BG1 1/17.

HC-SFS702BG1 1/17 Operation manual/Instructions/Model selection sample download link: /searchDownload.html?Search=HC-SFS702BG1 1/17&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Medium inertia power motor

HC-SFS702BK

Motor series: medium inertia, medium pow

MITSUBISHI

Medium inertia power motor

HC-SFS702

Motor series: medium inertia, medium pow

MITSUBISHI

Medium inertia power motor

HC-SFS702K

Motor series: medium inertia, medium pow

MITSUBISHI

Medium inertia power motor

HC-SFS702B

Motor series: medium inertia, medium pow